Quality Management

Our CQC system, which is de-signed to control and verify the work performed, is based on the following fundamental quality principles, among others:

-

Ensuring the highest quality of work by establishing, monitoring, maintaining and updating quality control procedures. This is accomplished by providing written instructions governing quality control procedures and practices to establish clearly defined responsibilities and authorities at the beginning of the project, to ensure quality is maintained;

-

Compiling accurate records of test results, certifications, and other required documentation that meet project-specific contractual requirements and standards;

-

Notifying the customer‘s representative of any quality deficiencies and proposed corrective actions and ensure that agreed upon corrective actions are properly implemented;

-

Providing qualified individuals responsible for managing and implementing an agreed CQC program; and

-

Ensuring high quality execution and project management by implementing strong, transparent documentation procedures.

Quality is the basis for the BAUER Group‘s global success and is therefore one of the company‘s key priorities. The trust in the quality of our products, services and equipment, which has developed over many years, is to be maintained and optimally expanded.

System

Our quality management system is based on ISO 9001 and the relevant legal and industrial norms.

All relevant processes of our company are methodically analyzed and documented. The processes are designed to increase product quality, for the continuous improvement process and thus increase customer and employee satisfaction. We use key performance indicators to regularly check whether the planned quality targets have been achieved. Deviations are analyzed and remedied in a timely manner.

Quality strategy

The quality strategy includes measures for quality assurance and quality control. All these steps are agreed on a project-specific basis and serve to minimize the construction risk and ensure the function of the final product. The steps are listed below as standard measures applied by Bauer for construction processes.

Quality assurance

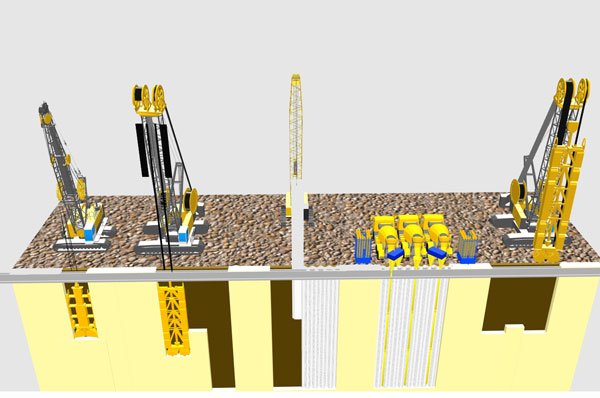

Constructability

-

Evaluation of soil conditions

-

Selection of the construction method

-

Selection of the (wall) geometry based on the Engineer requirements (i.e. width and depth and overlapping of elements)

-

Definition of a sequence of execution

-

Prediction of wear

Integrity of materials used

-

Trial mixes to ensure that their properties fulfill the requirements

-

Selection of an applicable mixing procedure for each mixed material – if required

Quality control:

-

Monitoring while execution

-

Monitoring of materials before use, during operation and after (… reaching the final depth)

-

Monitoring of equipment setup

-

Monitoring of excavated soil type and any anomalies Monitoring of used backfill materials with regard to fresh and hardened properties

Measurement of the (wall) geometry

-

Position of the center points of the individual wall elements

-

Inclination of individual (wall) elements

-

Rotation of individual (wall) elements – if required

Reports (in-time documentation)

-

Individual element: execution reports

-

As-built report for individual elements