Construction Material

Bauer´s Competency regarding Construction Materials is established and has been constantly progressing, as a result of:

-

In-house scientific research supported through academic cooperation with partner universities, investigating and assessing materials’ influence on the installation process and their influence on the final, integral quality of the wall or pile.

|

|

-

BAUER Spezialtiefbau GmbH cooperates worldwide with various organisations to specify standards and regulations. Amongst others we participate in the following groups:

-

We are a member of the German delegation for the Technical Committee TC288 of CEN in charge of European Standards for Execution of Special Geotechnical Works (EN 1538 Diaphragm Walls). We were also a member of the tremie concrete task group of the Piling and Foundation Specialists Federation (which compiled the “Guideline on Tremie Concrete for Deep Foundations”, published in 2012, by the Concrete Institute of Austral

-

Furthermore we have been chairing the joint Concrete Task Group of the EFFC, the European Foundation Contractors, and of the DFI, the Deep Foundation Institute (USA), established in January 2014. In 2018 the 2nd edition of the Guide to tremie Concrete for Deep Foundation was released. It recommends to adjust the design and quality control of tremie concrete in accordance with to latest developments and introduces these results to the European and international market, applicable for the revision of the concrete specifications for the next generation of CEN standards.

-

Consulting in operational works, hence giving project-specific advice in concrete design, raw materials and concrete testing, as well as quality assessment, in all construction phases from planning, calculating or finally executing the dam rehabilitation project.

-

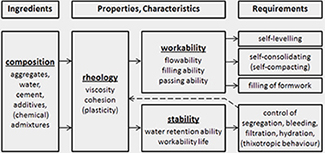

Bauer aims to support own projects in all matters and steps of materials’ use for deep foundation works. Regarding concrete for dam rehabilitation principal demands have to be specified in order to proof both sufficient fresh and hardened concrete properties:

-

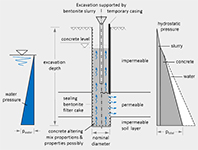

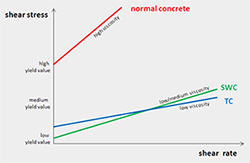

According to Bauer’s experiences gathered in own research, standards and consulting works the concrete, prior to its application in a project, must be properly designed, specifically tested and optimized. For placing concrete in deep excavations, the fresh concrete behavior must be understood and required properties must consequently be controlled throughout the concreting process.

|

|

|

|

-

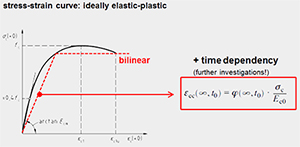

It is Bauer’s experience that the cut-off wall construction safety for both the ultimate and service limit state, in terms of its function as a water barrier, should not be based on the strength of the plastic concrete used but on its deformation capacity in or-der to gain from the material‘s plastic properties.

|

|

|

|

-

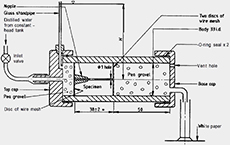

Permeability and erodibility, both must, within defined ranges, ensure the demanded serviceability of the wall

|

|