Grouting

GROUTING TECHNIQUES

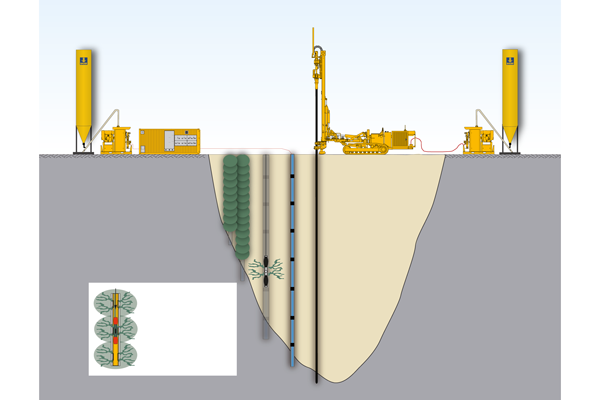

In granular soil:

-

Grouting with tubes-à-manchette (TaM) with annulus grout

Work sequence:

-

Drilling with temporary casing (optional)

-

Placement of annulus grout

-

Installation of TaM

-

Casing extraction (eventual)

-

Additional annulus grouting

-

Grouting of each manchette with double packer

In sound rock:

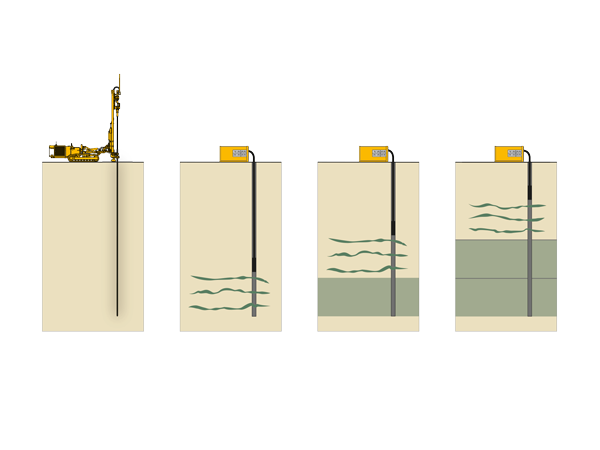

Upstage grouting: Procedure of drilling a hole to full (required) depth in one operation and grouting from the bottom of the hole towards the surface in successive stages, by setting a single packer at predetermined depths.

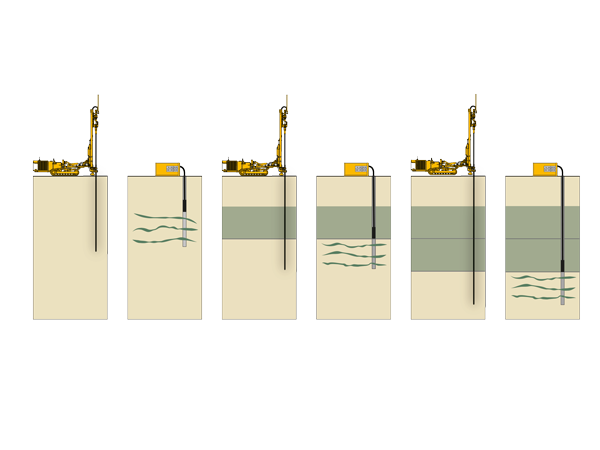

In weathered and unstable rock

Downstage grouting: Procedure of drilling a hole to a limited depth, setting a single packer and grouting the hole, per- mitting the grout injected around the hole to set sufficiently to prevent it from entering into the hole when the hole is cleaned.

-

Re-drilling through the hardened grout

-

Drilling the hole to the next deeper stage

-

Setting the packer at the bottom of the previously grouted stage or as directed by the Engineer and grouting of the new stage

APPLICATIONS

Pre-Treatment

Grouting for piling and diaphragm walls: Backfilling of cavities and large voids, either by gravity or by low pressure grouting by means of sleeve pipe.

Consolidation grouting underneath dikes and dam foun- dations: Injection of the first ground layer underneath the foundation that might be impaired by excavation and blasting.

Tightening and seepage mitigation

Grouting underneath dam and dike foundations: Granular soil

-

Pore permeation grouting with tubes-à-manchette (TaM)

-

Filling of soil pores in order to reduce the permeability and

-

to provide a seepage barrier underneath the (coffer-) dam foundation

Curtain grouting underneath dam and dike foundations: Rock

-

Fissure grouting

-

Grouting of fissures and cracks of the rock to provide a seepage barrier underneath the dam foundation