Jet grouting systems:

Single system: Process in which the disaggregation of the soil and its cementation are achieved by a high-energy jet of a single fluid, usually a cement grout. An adequate column diameter is already achieved with this system in homogeneous soils.

Double (air) system: Process in which the disaggregation of the soil and its cementation are achieved by one high- energy fluid (usually a cement grout), assisted by an air jet shroud as a second fluid to maintain the energy of the fluid jet over a longer distance. Wherever air support is advisable, larger column diameters can be achieved compared to the single system.

Triple system: Process in which the disaggregation of the soil is achieved by a high-energy water jet, assisted by an air shroud, both aimed to achieve a larger column diameter. Its cementing is simultaneously obtained by a separate noncutting grout jet.

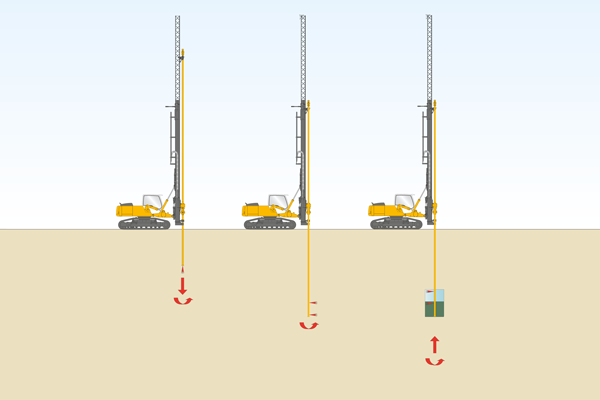

Sequence:

The execution of continuous jet elements can be achieved by single columns executed in the runner sequence, or by single columns executed in the pilgrim step mode. A fresh- in-fresh sequence aims to further integrate the individual columns of the longer planar elements.