Integrated Design

With our vast experience in construction methods the sequencing of production is optimized, combining equip-ment and material in the most effective way.

During construction production data is collected and merged, proving compliance between built and designed reality and providing experience for the next project. Inte-grated design requires the cooperation of all parties involved and good confidence into the realized design solution.

Punatsangchhu-II long injection drills for stabilization of a rockfall mass was executed within a tunnel. Per design the number and exact position of each drill was planned (left figure), so that the drill rig can approach the places well and execute them accordingly (right figure).

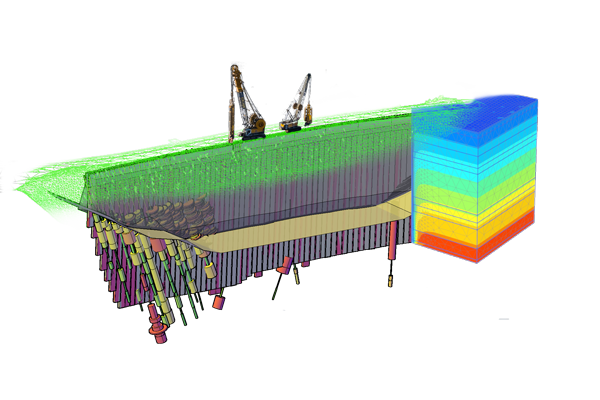

Construction model comprising data of different sources, Rosshaupten Dam, Germany.

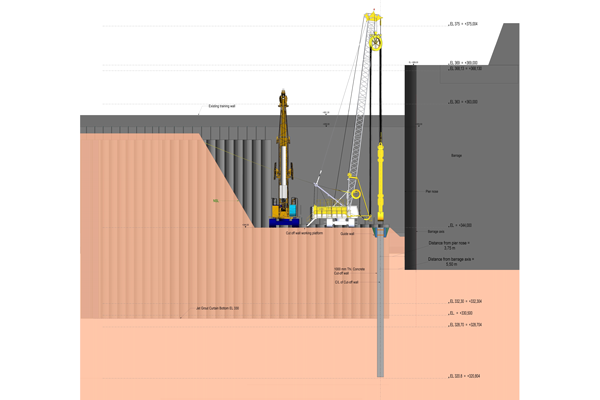

Ahead of the pr-treatment grouting works, seven exploratory boreholes were drilled, to a depth of up to 85 m, in order to take cores, and to obtain supplementary information about the unconfi ned compressive strength, the fracturing degree and the permeability of the existing rock. The per-meability was determined using the Lugeon packer test.

The data, which was monitored during all drilling works, also gave valuable information for the later grab and cutter excavation for the trenching. The data were digitalized and a 3D model and was produced step by step in real time, documentation and vizualization using Bauer’s specialist digitization B-project model.

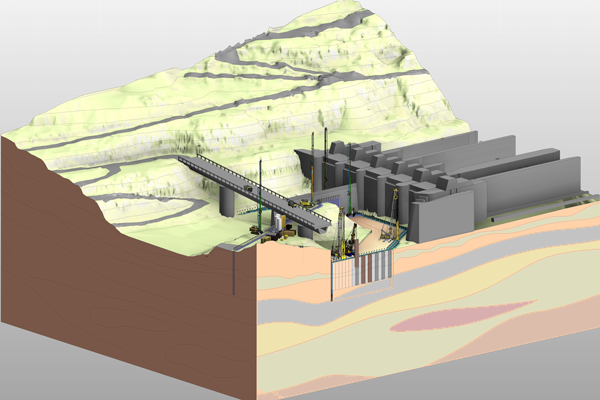

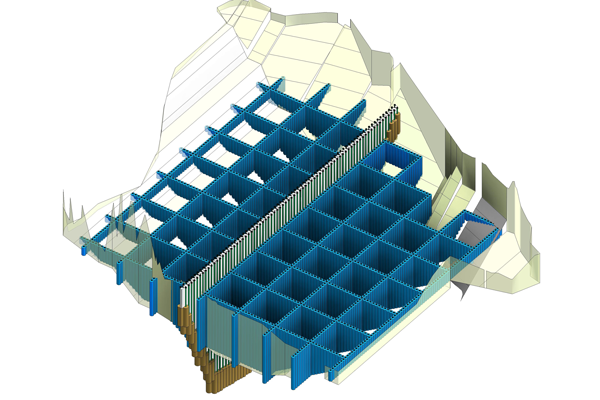

Teesta VI hydroelectric power project is located in the Himalayan mountains in India. The multidimensional project model includes topography, geology, existing and planned structures and the machinery for execution. Indi-vidual sections, showing the necessary detailing, are derived from the model. Typically, a cut-of wall is installed in the subsoil below the barrage. This wall ties into impermeable layers and prevents an underflow of the structure.

The figure shows a project model with jet-grouting, trench cutter and reinforcing of diaphragm wall in process.

This figure and the section through the barrage shows the cut-off wall with trench cutter in action. In the background aspect on the jet grout curtain in execution.

The total area is at risk of earthquakes. In consequence soil liquefaction of the sand layers with a complete failure of the earth dam can potentially occur.