Arun-III Hydroelectric Project

|

Arun-III Hydroelectric Project is a Run-of-River scheme, located at the River Arun in Sankhuwasabha District in the eastern development region of Nepal. The closest point of road access is Num Bazaar, which is close to the proposed dam site of the Project. The Arun River is one of the major tributaries of the Koshi River in the Sapta Koshi basin.

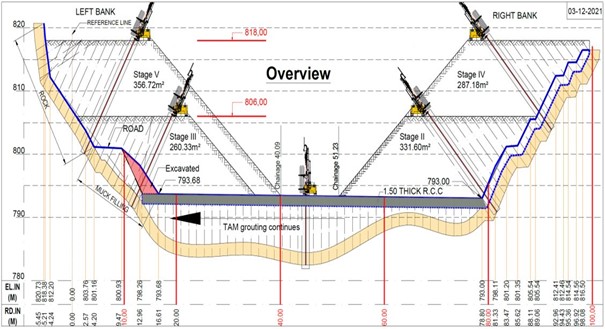

BAUER was awarded the execution of a grout curtain consisting of three rows at the upstream cofferdam. The grout curtain has temporary purposes and serves safety during the works on the main dam.

It is a very remote project in the Himalaya, which had a stringent time schedule, as the water level in the river normally rises by the end of March (due to thaw).

Drilling works were executed by means of the double head rotary drilling rig of KLEMM 909-02 D model with 1100 CFM compressor unit and the drilling system adopted is the Symmetrix Drilling System by casing advance method.

|

|

|

Grouting works were executed with 4 nos. of DP-63 OBERMANN Pumps with complete mixing plant setup and data logging arrangement.

Location

The site of the Arun III dam project is located approximately 307 km northwest of the national capital Kathmandu, Nepal

Scope of works Permeation grouting on upstream cofferdam, consisting of three rows

Geological conditions

Alluvium and colluvium, consisting of sand, gravel, pebbles and boulders, followed by bedrock (gneiss and schist). UCS values of bedrock and boulders in the river valley varying in a range of 30 MPa to 110 MPa

|

|

Equipment

Construction period

November 2021 – April 2022

|

|

Figure showing a typical cross section of upstream coffer dam with grouting scheme